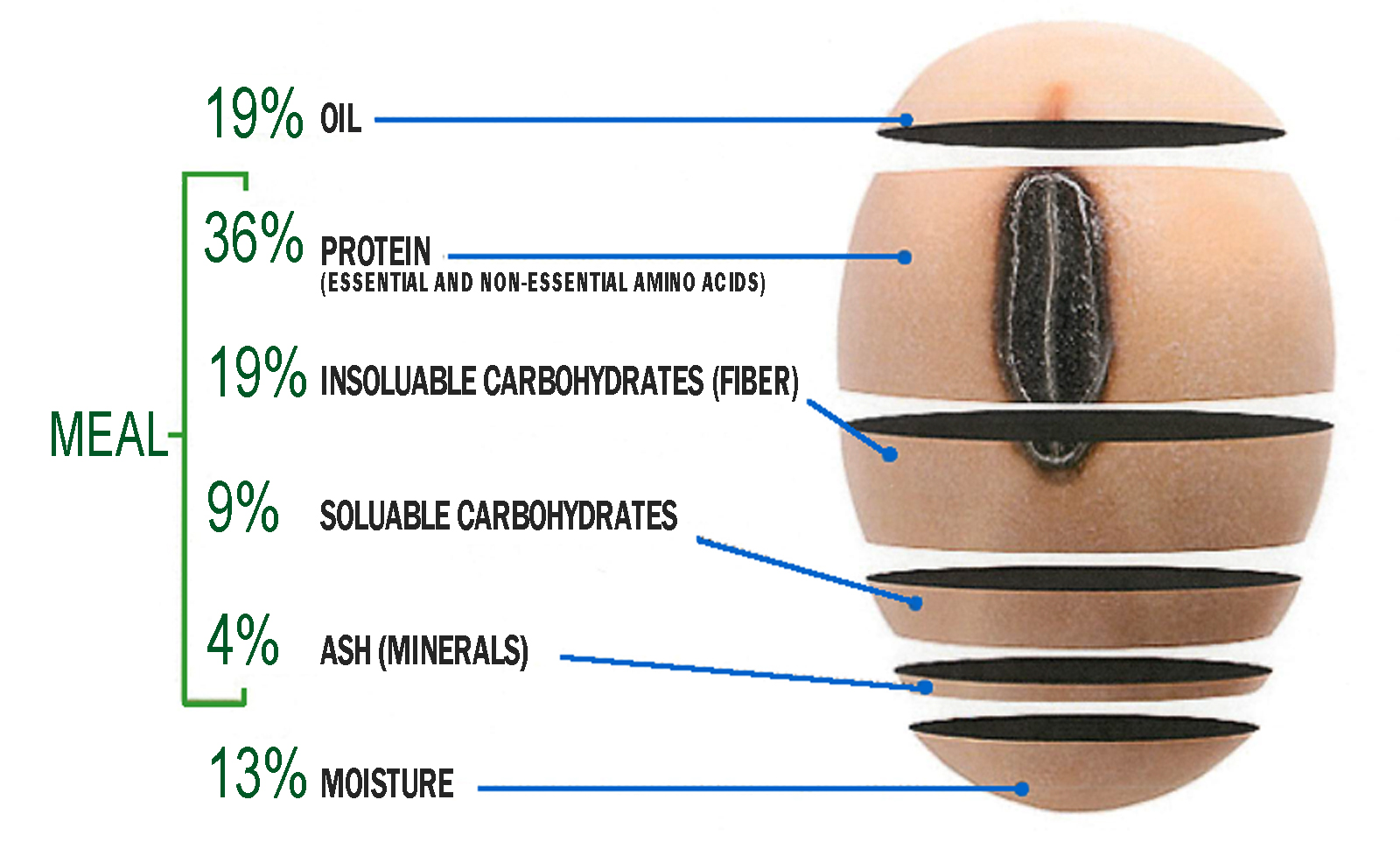

Soybean Composition

Composition of a Soybean

Soybean Processing: Soybeans are cleaned, then dried, cleaned again, cracked, and dehulled. These cracked beans are then conditioned (heated) and rolled into flakes. At this point, the oil is removed from the flakes by a solvent wash in an extractor. The oil is then separated from the solvent mixture. The extracted crude oil is refined, bleached, and deodorized, resulting in clear and odorless soybean oil, suitable for edible and non-edible uses.

Soy Oil: Soybean oil is a highly adaptable product, not only for foods, but also for industrial use as an ingredient in paints, plastics, pharmaceuticals, printing inks, oleochemicals, cleaners, and biofuels.

Soy Meal: After removal of the soybean oil, the remaining defatted flakes are toasted, dried, and ground for use as a protein source for livestock, pets, human food applications, and industrial uses. Soybean meal is the world’s most important source of protein for poultry and livestock.

Soy Flour: Soy flour contains more than 50% protein, and is used in many commercial bakeries.

Soy Hulls: Contain a high level of very digestible fiber and are further processed into fiber bran breads, cereals and snacks; and feedstuffs for the dairy and cattle industries.